Rendering: the original “recycling” industry

Rendering: the original “recycling” industry

Rendering companies play an important role in the communities they serve. How?

- By reclaiming and repurposing more than two million tons of organic materials every year.

- By generating more than five times fewer greenhouse gas emissions compared to sending organic materials to a landfill.

- By taking the pressure off landfills, which would quickly become overwhelmed without these mass transformation sites.

- By respecting our planet’s limits, and being a key player in the circular economy.

- By offering the greenest possible option for treating agri-food industry by-products.

- By reclaiming and repurposing more than two million tons of organic materials every year.

- By generating more than five times fewer greenhouse gas emissions compared to sending organic materials to a landfill.

- By taking the pressure off landfills, which would quickly become overwhelmed without these mass transformation sites.

- By respecting our planet’s limits, and being a key player in the circular economy.

- By offering the greenest possible option for treating agri-food industry by-products.

- By reclaiming and repurposing more than two million tons of organic materials every year.

- By generating more than five times fewer greenhouse gas emissions compared to sending organic materials to a landfill.

- By taking the pressure off landfills, which would quickly become overwhelmed without these mass transformation sites.

- By respecting our planet’s limits, and being a key player in the circular economy.

- By offering the greenest possible option for treating agri-food industry by-products.

At Sanimax, we are proud to transform it all

Creating value in new ways: that’s what the circular economy is all about.

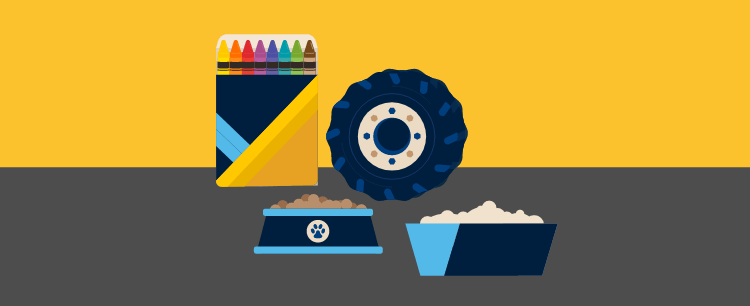

With this principle as our guide, we repurpose more than two million tons of organic materials every year across the American continent. This means less waste in landfills and more everyday items made from renewed materials. Driving your car, painting your house, feeding livestock… Our value-added ingredients can be found in a number of everyday tasks.

Rendering: an impactful recycling process

In North America, half of what is created by the livestock industry does not make it to our plates. Sanimax reclaims what’s left over.

Instead of being thrown away, these unconsumed by-products are transformed into value-added ingredients.

Our high-quality industrial ingredients are used to manufacture everyday items. That’s the magic of the circular economy!

Rendering: the eco-friendly option

Transporting visibly unusable organic residues to modern facilities and then transforming them into new ingredients is an environmentally friendly way to dispose of these materials. Studies* have shown that the associated greenhouse gas emissions are much lower than other potential solutions.

Comparing greenhouse gas emissions (GGE) for 1,000 kg (2,205 lbs) of meat by-products

Rendering industry

Industrial composting

Anaerobic digestion

Frequently asked questions

The circular economy is an economic system that aims to reduce the consumption and waste of primary materials as much as possible. This model, which is based on recycling, works to eliminate the idea of waste. Supporting the circular economy means preserving our planet’s resources.

Rendering is a process that is used to treat agri-food by-products by transforming them into oils, greases, and proteins. In the context of the circular economy, these value-added ingredients are then used by manufacturing companies that create everyday products. Check out this animation to better understand how our process unfolds.

Each year, we invest a significant amount in making sure our company can happily coexist with nearby communities. We are aware that our neighbours have increasingly high expectations, and that we must minimize the impact of our operations. To facilitate a more harmonious coexistence, Sanimax is more attentive than ever to municipal authorities and communities. Learn more about our commitments.

The raw materials we collect can generate odours around our facilities. These organic materials naturally emit odours, especially in warm weather. Year after year, we continue to invest in technologies that have already strengthened the stability and performance of our facilities, such as automation and artificial intelligence. These improvements allow us to operate more efficiently and reduce unforeseen events, ultimately helping to minimize odour emissions.

Check out this animation to better understand how our process unfolds.

Depending on the territory, Sanimax produces proteins, greases and oils, as well as ingredients that are used in renewable fuels and pet food. We contribute to the essential role that rendering plays in the food production chain. Each year on the American continent, our industry produces more than 4.5 billion kilos (9.92 billion pounds) of grease and oil, and more than 4.1 billion kilos (9.04 billion pounds) of protein.

No, on the contrary! We reclaim a huge quantity of by-products that, left unrendered, would end up as unwanted organic waste. What’s more, rendering captures five times more carbon compared to the emissions it generates*. That’s the equivalent of taking more than 12,000,000 cars off the road across the Americas.

Rendering is also the most efficient treatment option for agri-food industry by-products (compared to burying, composting, anaerobic digestion, or simply leaving them on the ground). In addition to releasing fewer greenhouse gases, the treatment process only takes a few hours. Check out this animation to better understand how our process works.

Burying organic residues releases five times more greenhouse gas emissions compared to rendering.* If our industry didn’t exist, the colossal quantity of organic by-products that would need to be buried in a landfill would have serious environmental consequences.

*Source: Gooding, C. and D. Meeker. 2016. Review: Comparison of 3 alternatives for large-scale processing of animal carcasses and meat by-products. Prof. Ani. Sci. (Vol. 32, Issue 3, p259–270)